Custom Heatsinks

The electronic components industry has developed various cooling solutions, including liquid cooling systems, heat pipes, and heatsinks. Among these solutions, custom heatsinks are gaining popularity as an effective way to manage heat in high-power and high-performance electronic systems. Custom heatsinks are designed to meet specific requirements, such as size, shape, and thermal performance, making them an ideal solution for complex electronic devices.

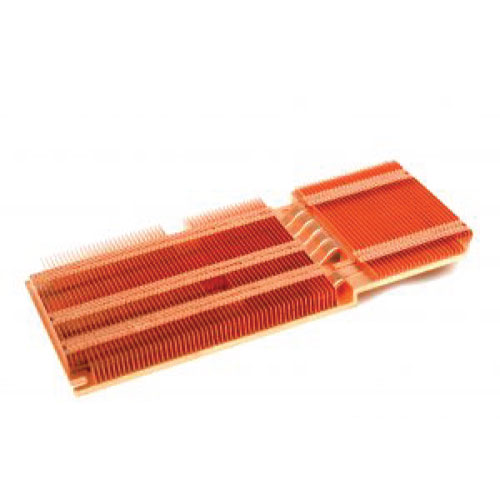

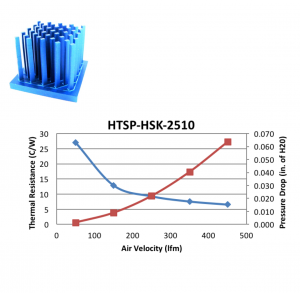

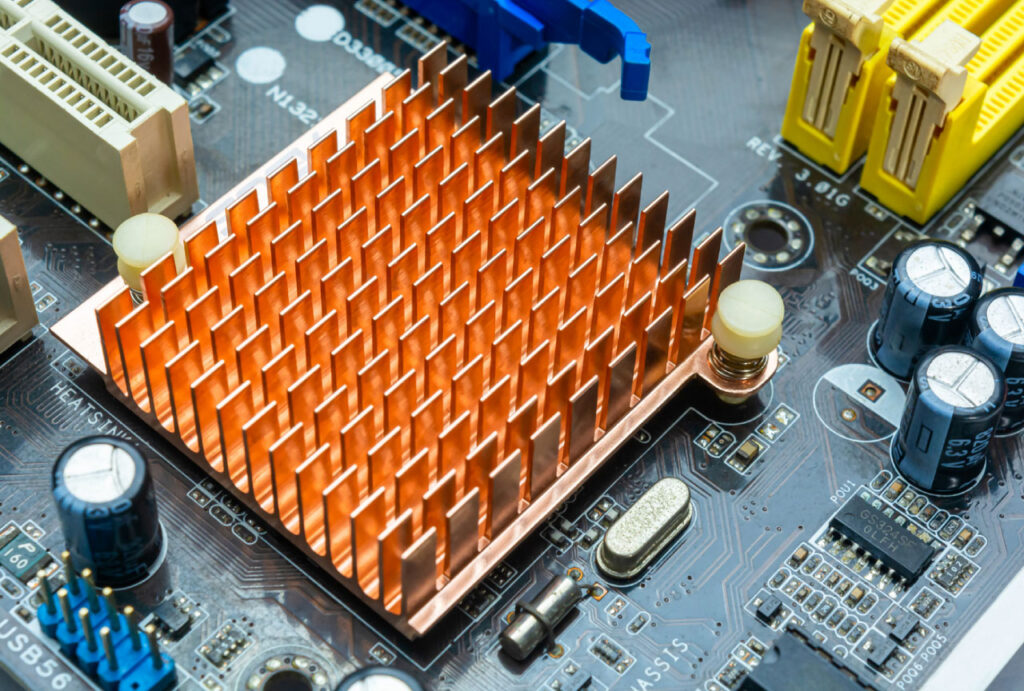

Stacked Fin Heatsinks

Heatscape’s custom stacked fin heat sink solutions offer better performance when compared to typical extrusion heatsinks, due to thinner fin profiles leading to higher surface area and lower pressure drop. With our advanced engineering and manufacturing expertise, Heatscape has been able to cool some of the most demanding thermal challenges in the telecom, networking, and electronics industries.

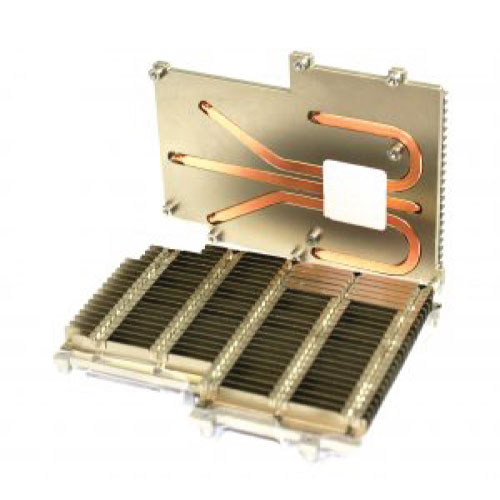

Heatpipe Assemblies

By embedding heatpipes into the base of a heatsink, the spreading capability of the base, and therefore the overall heatsink performance can be greatly improved. In addition, evaporator/condenser heatpipe assemblies can also be used to move heat from a high powered component in a tightly constrained area, to a region where a larger, more conductive fin array can be placed. Heatscape a heat pipe manufacturer specializes in incorporating heatpipes into a variety of thermal solutions.

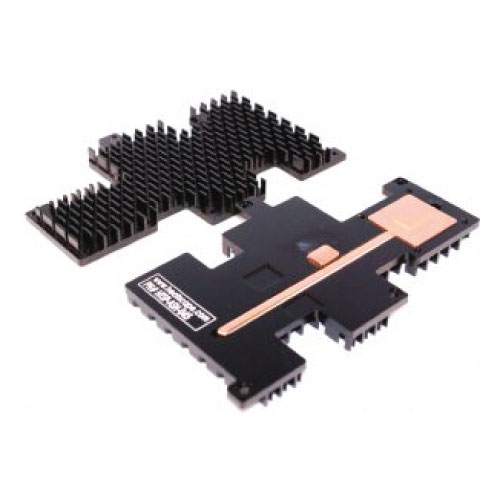

Custom Vapor Chamber Heatsinks

Today’s CPUs, GPUs, and high performance ASICs are continually increasing their capacity, speed, and power, while being placed into smaller and more compact form factors, leading to increased power density. This leads to greater challenges from a thermal management perspective. Vapor Chamber Heat sinks, which work based on heatpipe principles, offer improved spreading efficiency, higher thermal conductivity, and reduced weight for these applications. Heatscape’s engineering team can deliver custom vapor chamber heat sinks solutions in custom sizes and shapes, including single and multi-stepped vapor chamber bases.

Aluminum Extrusion Heatsinks

Aluminum extrusion heat sinks are an effective way to cool heat producing components in a cost-effective manner. High-end custom extrusion designs can be used for more thermally challenging applications, while simpler straight-fin or cross-cut fin designs can be used for lower powered ones. Aluminum extrusion heat sinks can also be customized with embedded heat pipes, captive mounting hardware, and color anodizing.

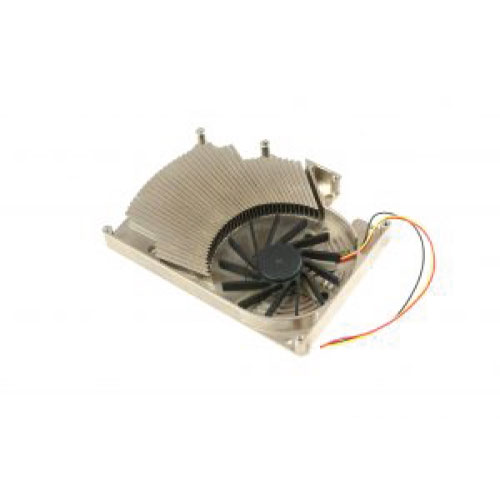

Active Heatsinks

Our active heat sinks can be custom built according to your needs. With the rising functionality and computing power of graphics boards and GPUs comes greatly increased thermal challenges. Heatscape has designed, developed, and manufactured numerous graphics card thermal solutions for both 1-slot and 2-slot products using a variety of innovative methods. Independent floating core solutions are also available for use in dual GPU applications to alleviate tolerance issues associated with the heights of the 2 chips.

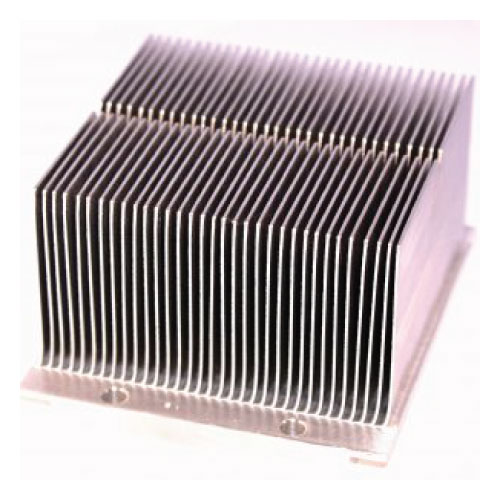

Skived Fin Heatsinks

Skiving is a manufacturing process where thermal solutions are formed by shaving one solid block of copper or aluminum into a finned heatsink. This method eliminates the resistance layer that is present with the solder layer in stacked fin heatsinks since skived fins are built from a single piece of metal. Skived fin heatsinks also require minimal tooling charges, which makes it a cost-effective solution. Skived heatsinks can also be customized with embedded heatpipes to add a performance boost if needed.

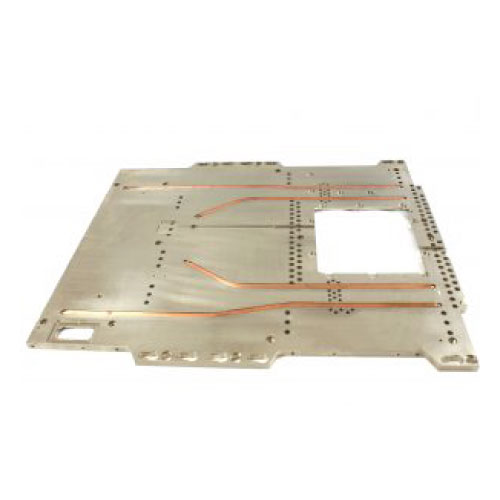

Advanced Metal Fabrication

Heatscape specializes in advanced metal fabrication products to go along with our thermal solutions.

PCI-E Heatsinks

PCI-E boards are becoming more high powered, requiring the need for customized and advanced heatsink designs.

About

How the technology works

Custom heatsinks are designed to maximize the surface area of a device and enhance its ability to dissipate heat. They are typically made of aluminum, copper, or a combination of both, which have high thermal conductivity, allowing heat to move away from the device and spread over a larger area. The heatsink’s fins or blades are custom-designed to increase the surface area, which enhances the heat transfer by allowing more air to flow through it.

Custom heatsinks are designed to fit specific devices and applications, and as such, they can take many different shapes and sizes. They can be manufactured using various techniques, such as extrusion, casting, or forging, depending on the desired shape and performance. Additionally, custom heatsinks can be combined with other cooling solutions, such as fans or heat pipes, to enhance their cooling capabilities.

Advantages and limitations

The primary advantage of custom heatsinks is their ability to meet specific design requirements. They can be custom-designed to fit the device and the application, ensuring optimal thermal performance. Additionally, custom heatsinks can dissipate large amounts of heat efficiently, making them suitable for high-power and high-performance applications.

However, custom heatsinks can be more expensive than standard heatsinks, as they require custom design and manufacturing. Additionally, the design and manufacturing process can take longer, adding to the lead time of the project.

Applications

Custom heatsinks are widely used in high-power and high-performance electronic systems, such as power electronics, telecommunications, and aerospace. They are used to cool devices such as power transistors, IGBTs, laser diodes, and LED arrays. Additionally, custom heatsinks can be used in automotive and industrial applications, where reliability and performance are critical factors.

Conclusion

Custom heatsinks are an important part of the cooling solutions in the electronic components industry, providing an effective way to manage the heat generated by electronic devices. They are designed to meet specific requirements, ensuring optimal thermal performance and reliability. While custom heatsinks can be more expensive and time-consuming than standard heatsinks, their ability to meet specific design requirements makes them an essential component in high-power and high-performance electronic systems.